Plaćanje pouzećem – trenutno nije moguće odabrati kao način plaćanja za online narudžbe - isključivo za narudžbe putem telefona ili e-maila.

Uplatom na račun – putem e-pošte šaljemo podatke potrebne za uplatu iznosa narudžbe.

Kartično plaćanje - online putem Visa, MasterCard®, Maestro® i Diners kartica.

Böker Plus ME 109 Damast Limited Edition Messerschmitt Bf 109

375,00 € sa PDV

Böker ME 109 Damast, from fighter aircraft to limited edition knife. The steel we were able to source for our Damascus project comes from a Messerschmitt Bf 109 E-series which was shot down by a Royal Air Force Supermarine Spitfire near the village of Ashford, Kent, UK in 1940 in the Battle of Britain. The parts are the rear plate of the pilot’s seat armor and the propeller shaft bearing sleeve. These are forged in US by famous Chad Nichols into a high-carbon and edge-holding 80-layer Damascus steel using a variant of the Wave-Pool pattern.

| Brend | |

|---|---|

| Materijal sječiva | , |

| Debljina sječiva mm | |

| Dužina sječiva cm | |

| Ukupna dužina cm | |

| Masa (grama) | |

| Materijal rukohvata | , |

| Način otvaranja | |

| Mehanizam kočnice | |

| Zemlja porijekla | , , |

Our new project pays tribute to the Messerschmitt Bf 109E, which was the backbone of the Luftwaffe’s fighter force during World War II, and consists of various reused aircraft parts recovered through a collaborative agreement with a private preservation group based in the United Kingdom. These historic parts come from a crashed Luftwaffe Bf 109 “E” series during World War II, shot down by a Royal Air Force Supermarine Spitfire in 1940, during the Battle of Britain, in an air combat near the British village of Ashford, Kent, about 100 kilometers southeast of London. As many as 180 Messerschmitts were shot down during this phase of the war.

The Messerschmitt Bf 109 has been in production since 1935 and, with a production run of around 33.000 machines, is the most widely sold combat aircraft in the history of aviation. Officially, the type designation Bf 109 was never changed even after the BFW (Bayerische Flugzeugwerke) was renamed Messerschmitt AG. However, since all aircraft types later developed by Messerschmitt received the model abbreviation Me, the name Me 109 also became established in the public consciousness for the Bf 109.

In the 1930s, it marked the step towards a new generation of low-wing fighter aircraft with a closed cockpit, retractable landing gear and an all-metal construction of wings and fuselage. This new structure withstood far greater loads than the fabric-covered tubular constructions that had been which also had the disadvantage of immense air resistance due to the necessary transverse bracing. As a result, the more compact and stable design of the Messerschmitt enabled higher speeds with tighter radii during the turns and dives so crucial for fighter pilots.

The Bf 109 was armed with two 20 mm caliber MG FF machine cannons in the wings and two 7.92 mm caliber MG 17 machine guns. The latter were mounted directly in front of the pilot and coupled to the propeller shaft of the 1,000 hp Daimler V12 engine via a breaker gear. In this way it was possible for the machine guns to fire through the circular path of the rotating propeller without the projectiles hitting the rotating propeller blades. The machine guns were thus very close to the pilot’s line of sight.

The steel we were able to source for our Damascus project comes from a Messerschmitt Bf 109

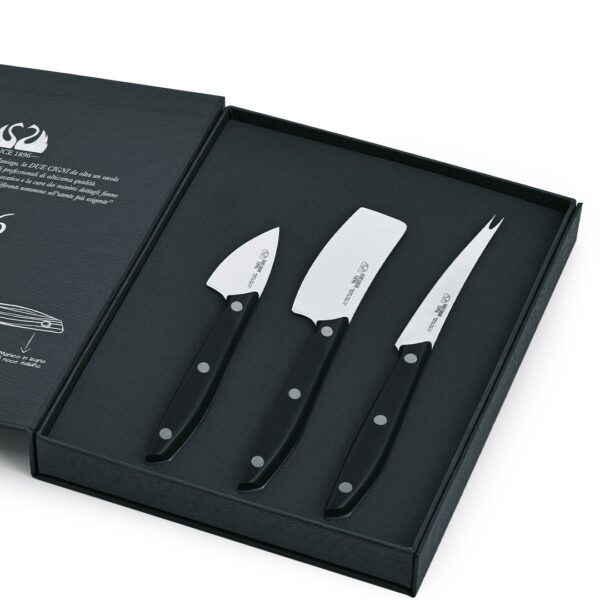

E-series which was shot down by a Royal Air Force Supermarine Spitfire near the village of Ashford, Kent, UK in 1940 in the Battle of Britain. The parts are the rear plate of the pilot’s seat armor and the propeller shaft bearing sleeve. These are forged in US by famous Chad Nichols into a high-carbon and edge-holding 80-layer Damascus steel using a variant of the Wave-Pool pattern, which is not particularly contrasty but effective in suggesting a propeller’s rotary motion. The opening at the back of the blade base has the unmistakable shape of a pilot’s cockpit and is visible when the knife is closed and open. The false edge near the blade tip recalls the line of the recesses for the machine guns mounted on the engine cowling, also known as Motorkanone. The flipper for the blade opening takes up the outline of the Messerschmitt Bf 109E landing gear. The carbon fiber scales are made by the Lithuanian company Fat Carbon, which employed a multi-layer “Toxic Storm” coloring with a green base and yellow highlights, typical of Luftwaffe fighters of this era. The knife’s frame is made of titanium, and the blade is locked open using a proven frame lock system. A titanium clip allows the knife to be carried in the “tip up” position. Delivered with a high-quality case for storage and a certificate of authenticity.

Samo logirani kupci koji su kupili ovaj proizvod mogu napisati recenziju.

NAČINI PLAĆANJA

PODACI O DOSTAVI

Pošiljke isporučujemo putem DPD dostavne službe svaki radni dan,

najčešće u roku 24 sata od zaprimanja narudžbe i/ili uplate.

DOSTAVA NA PODRUČJU EU

Hrvatska: dostava pošiljaka iznosi 5 €

Zona 1: Slovenija:

dostava pošiljaka iznosi 10 €

Zona 2: Hungary, Slovakia, Austria, Czechia, Poland, Germany, Belgium, Netherlands, Luxembourg, Italy, Denmark, France, Ireland, Lithuania, Latvia, Sweden, Estonia, Spain, Portugal:

dostava pošiljaka iznosi 25 €

Zona 3: Bulgaria, Finland, Greece, Romania:

dostava pošiljaka iznosi 39 €

Dostavu izvan područja EU ne vršimo.

Recenzije

Još nema recenzija.